Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register now2026 Top Injection Molding Machine With Robot Features?

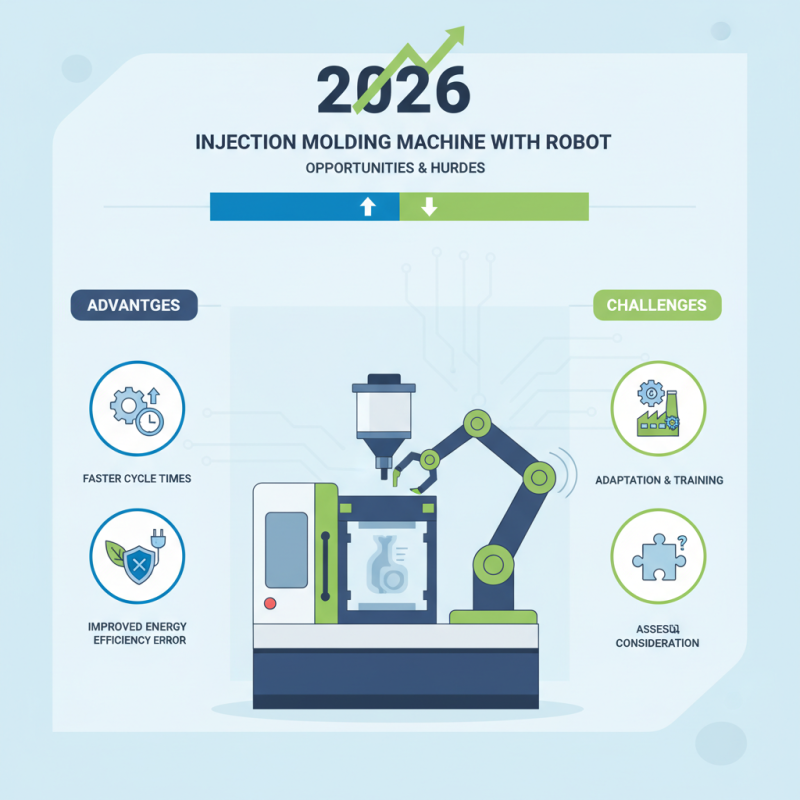

As the manufacturing landscape evolves, the need for efficiency rises. The "Injection Molding Machine With Robot" stands at the forefront of this change. It combines precision molding with robotics to streamline production. This innovation enhances automation and minimizes human error.

Moreover, the integration of robotics with injection molding machines transforms the industry. Faster cycle times and improved energy efficiency are just the beginning. However, businesses must assess their unique needs. Not every facility will benefit equally from this technology. Some may face challenges in adaptation and training.

Investing in advanced machinery is not a one-size-fits-all solution. Companies need to reflect on their workflows and goals. The "Injection Molding Machine With Robot" offers many benefits, yet it requires careful consideration. Understanding both the advantages and the hurdles is crucial for success.

2026 Trends in Injection Molding Machine Technologies

The injection molding industry is undergoing significant transformations. In 2026, automation will dominate. Robots are becoming integral to injection molding machines, enhancing speed and precision. A recent report highlights that automated systems can increase productivity by up to 30%. This shift will redefine production efficiency.

Moreover, sustainability is a key trend. Industry data suggests that the demand for eco-friendly materials will grow by 25% in the next three years. Companies need to adapt. They must prioritize energy-efficient machines and recyclable materials. There is greater emphasis on reducing waste in the injection molding process.

Tips: Invest in training for your team. Understanding new technologies is crucial. Embrace modular machine designs. They offer flexibility and scalability for future needs. Lastly, monitor industry advances regularly. Staying informed helps in making timely improvements. Keeping pace with these trends is essential for staying competitive.

Key Features of Robot Integration in Injection Molding

In the world of injection molding, the integration of robotic features has proven to be transformative. Recent data reveals that up to 70% of manufacturers now leverage robotic arms to enhance production efficiency. These robots can handle complex tasks, such as material loading, part removal, and quality inspection. This level of automation reduces manual labor and minimizes human error.

Moreover, the adaptability of robotic systems allows manufacturers to easily switch between different product lines. This flexibility is crucial in today’s fast-paced market. According to a report by the International Federation of Robotics, the demand for automated solutions in injection molding has seen a 15% annual growth.

Tip: Consider investing in modular robotic systems. They can save time and costs during setup.

Furthermore, robot integration not only boosts production rates but also improves precision. The accuracy in part placement can achieve tolerances within 0.01 mm. However, it’s essential to reflect on the training needs for staff. Operators must understand how to work alongside robots effectively to avoid potential operational hiccups.

Tip: Regular training enhances collaboration between human and robotic systems.

Incorrectly calibrated robots can lead to defective parts, impacting overall quality. This highlights the importance of continuous monitoring and maintenance. Implementing regular reviews can help avoid these pitfalls, ensuring a smooth operational workflow.

Comparative Analysis of Top Injection Molding Machines

The injection molding industry is evolving rapidly. With the integration of robotic features, machines are becoming more efficient. These machines can handle complex operations with precision. However, many users still experience a learning curve. Understanding the functionalities of each model is crucial.

Comparing top injection molding machines reveals similarities and differences. For instance, some machines offer faster cycle times but may lack advanced automation. Others excel in energy efficiency but are slower. Users need to evaluate their production needs. The balance between speed and cost-effectiveness can be tricky.

The implementation of robotics in these systems raises questions. While they enhance productivity, they also require technical maintenance. Many manufacturers struggle with this aspect. Investing in training can help alleviate some of these issues. It is essential to reflect on the overall cost and benefits before making a decision.

Benefits of Automation in Injection Molding Processes

Automation in injection molding processes brings numerous advantages. One key benefit is enhanced efficiency. Robots can handle repetitive tasks with precision. This reduces production time significantly. They work tirelessly, ensuring that cycles are shorter and outputs are higher.

Tips: Consider the layout of your workspace. Streamlining the flow can enhance robotic efficiency.

Another benefit is improved quality control. Robots can perform inspections to ensure parts meet specifications. This reduces errors and waste, leading to cost savings. Yet, some may worry about the initial investment. Investing in this technology can seem daunting. However, the long-term savings often outweigh the initial costs.

Tips: Regular maintenance of robotic systems is crucial. It prevents downtimes that can stall production.

The integration of robots requires training. Operators must understand both the technology and the process. Some challenges may arise during this transition. It's essential to remain adaptable and open to learning. Adopting new automation technology can seem overwhelming but can lead to significant advancements in production capabilities.

Future Prospects for Injection Molding with Advanced Robotics

The integration of advanced robotics into injection molding is transforming the industry. A report from MarketsandMarkets predicts that the global injection molding market will reach $320 billion by 2026. Automation is a key driver of this growth. Robotic arms streamline processes, enhancing precision and efficiency. These machines reduce cycle times significantly, leading to quicker production rates.

Moreover, the workforce landscape is changing. According to a study by the International Federation of Robotics, around 1.7 million industrial robots are expected to be deployed globally by 2025. Although this is promising, it raises concerns about job displacement. Workers may need to adapt their skills. Upskilling programs will be crucial in this transition.

However, the adoption of robotics comes with challenges. High initial costs and technical complexities can deter smaller manufacturers. They may struggle to compete with larger entities embracing automation. Reflecting on these factors, it becomes clear that while robotics offers innovation, the industry must also address potential social impacts. Balancing technology and human resources will be essential for sustainable growth.

2026 Injection Molding Machines with Robotics Features

This chart presents the expected performance metrics for injection molding machines with robotics features in 2026. It covers speed, precision, cost, energy efficiency, and maintenance frequency, reflecting advancements in technology in the injection molding sector.